PROFILES EXTRUSION

SECTORS: Car body | Solar | Electric | Ilumination | White Goods | Fittings | Construction

T4, T5, T52, T6, T66

T4, T6

T4, T6

Possibility of extrusion in alloys of the 6000 series

FACILITIES

Our capacity allows us to generate projects according to the needs of our clients.

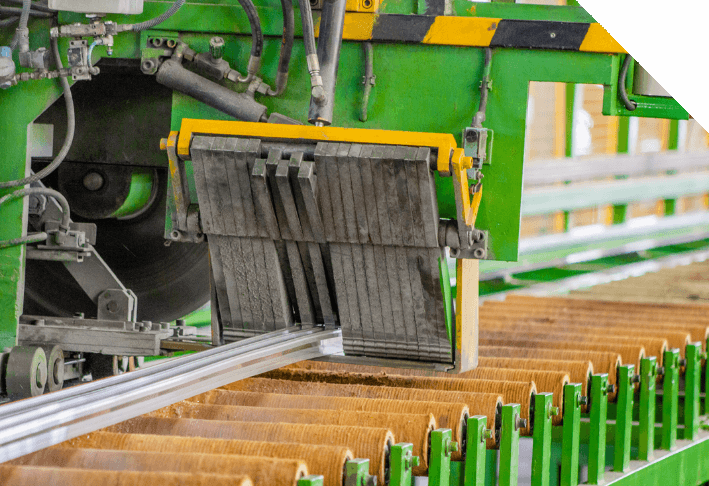

EXTRUSION PLANT

2 Aging Furnaces Capacity – 6,615 lb (3,000 kg), 22 ft (6.7m) length / each

Estrusion Press 2 – 2,500 ton – billet de 8” Capacity : 1´320,000lbs (600,000 Kg) / mothly

1 Aging Furnace Capacity – 22,050 lb (10,000 kg),53ft (16.15m) length / each

CASTING

Casting Unit

6” (152mm) diameter x 240” (6,100mm) length

Homogenized Furnace Capacity – 22,050 lb (10,000 kg)

CUTTING AREA

CNC – 90° cutting machine – high precisión

(+/- 0.005”) (+/- 0.15mm) – Automotive quality.

QUALITY LABORATORIES

Spectrometer

Optical Comparator

Lathe

Durometer

Height meter

UV radiation Chamber

Cyclical resistence equipment

Salt Corrosion Chamber

Herrign test

Thermal test

Wind resitance test

Water Permeability test

WAREHOUSE

12,917 square ft (1,200 m2) with racks

ADDED VALUE

CNC Machine.

We analyze and manage your design projects for the manufacture of extrusion dies.

We carry out the national or international shipment management.

Low volumes and delivery times.

According to the requirements and standards of each..

Avenida Europa #311

Parque Industrial Logistik II

Laguna de San Vicente

Villa de Reyes, San Luis Potosí, México

ZIP.: 79525

Phone.: +52 444 212 14 81

servicioaclientes@simax.com.mx

Comunícate con nosotros:

Avenida Europa #311, Parque Industrial

Logistik II, Laguna de San Vicente, Villa de

Reyes, San Luis Potosí, México. CP.: 79525

Teléfono.: +52 444 212 14 81

servicioaclientes@simax.com.mx